Programmable controllers are industrial, programmable circuits used to control production processes. They are a low-cost and powerful alternative for directing and managing automated systems in all types of industries.

Learning Objectives

- Describe the historical evolution of programmable controllers

- Understand the role and importance of programmable controllers in automated processes

- Become familiar with the most typical applications of programmable controllers

Language: English

Micro-module: No

Micro-module Series: No

Digital electronics is the foundation of programmable logic controllers. Digital devices like PLCs use circuits programmed with a logic system to determine the output based on one or more inputs. Understanding how digital circuits work will help you better understand how a PLC operates.

Learning Objectives

- Define digital electronics

- Identify the number systems used by PLCs

- Identify the data types used by PLCs

- Identify and define the logic gates used in PLC programming

- Understand how logic gates function

- Identify the symbols for logic gates

Language: English

Micro-module: No

Micro-module Series: No

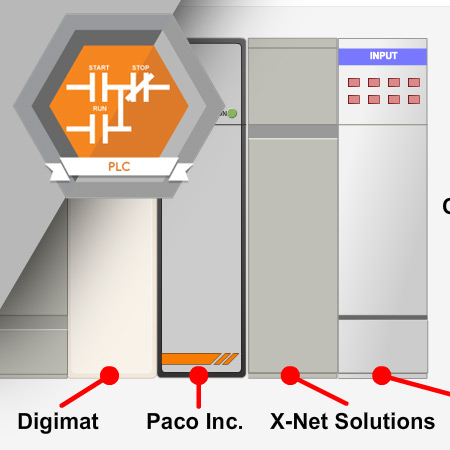

Programmable controllers are frequently used in automatic control systems to control machines and processes. There are many different types and functions of programmable controllers in use today. Their applications are diverse, ranging from commercial to residential to industrial.

Learning Objectives

- Describe the different types of programmable controllers

- Identify the functions of the different types of programmable controllers

- Provide examples of typical applications for the different types of programmable controllers

Language: English

Micro-module: No

Micro-module Series: No

A PLC is built using the same basic components that are found in the personal computer at your home, school, or business. Because a PLC is used for industrial operations, specialized components are available that allow it to communicate with and control automated equipment.

Learning Objectives

- Identify the main components of a generic PLC

- Identify the sub-components of each main component

- Identify the various configurations of the main components

Language: English

Micro-module: No

Micro-module Series: No

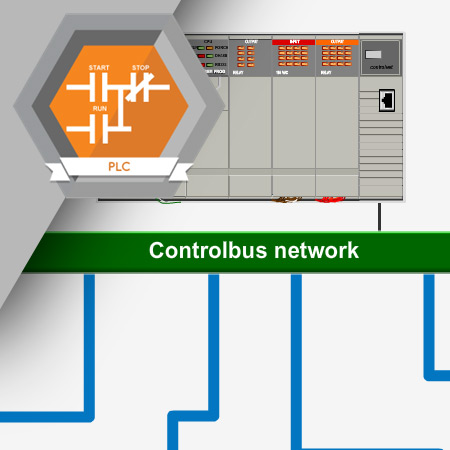

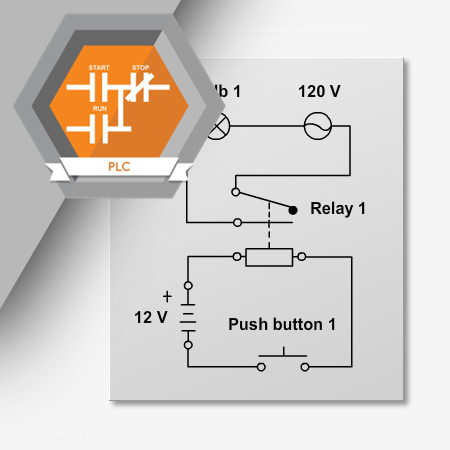

PLCs are designed to be integrated with machines and devices to monitor and control automated processes. The integration is achieved through a series of electrical connections that allow the PLC to receive, process, and send electrical signals.

Learning Objectives

- Become familiar with the different ways of providing electrical power to a PLC

- Identify the different methods of connecting sensors and devices to input courses

- Identify the different methods of connecting devices to output courses

Language: English

Micro-module: No

Micro-module Series: No

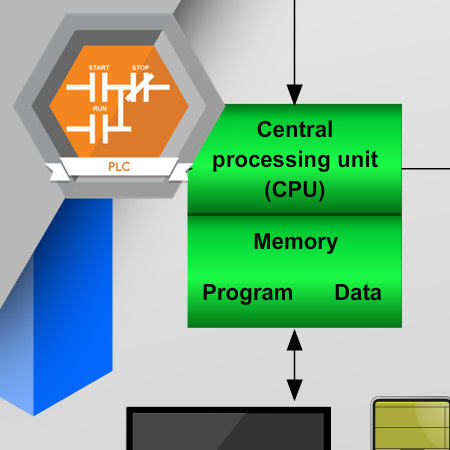

The CPU contains the elements that form the intelligence of the PLC. Understanding the components of the CPU and how they interact will help you gain the base knowledge needed to understand a PLC user program.

Learning Objectives

- Identify the different sections of the CPU and their interactions

- Describe how the information and data are processed and stored inside the CPU

- List different areas of memory

- Identify the elements of a logical address

Language: English

Micro-module: No

Micro-module Series: No

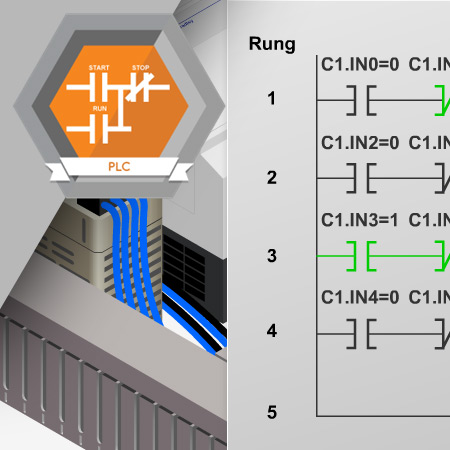

In order for a PLC to control an automated machine or process, it must be given a set of instructions. These instructions, or user programs, tell the PLC what inputs to monitor, how to process the data, and how to respond to the inputs.

Learning Objectives

- Identify the four steps a PLC performs during operation

- Define the term input scan

- Define the term program scan

- Define the term output scan

- Identify the symbols representing normally open and normally closed contact relays

- Identify the two structures used for programming

Language: English

Micro-module: No

Micro-module Series: No

In this course, you will see examples of real world PLC operations and examples of ladder logic and GRAFCET programs used to control the PLC.

Learning Objectives

-

Understand solutions for different real world applications using PLCs

Language: English

Micro-module: No

Micro-module Series: No