Compressed air treatment is a process that includes filtering, lubricating, and regulating the pressure of the air. This process requires the use of several specialized devices.

Learning Objectives

- Explain the need for compressed air treatment

- List the types of air treatments

- Explain the need for air filtration

- List the types of air filters

- Explain the need for air pressure regulation

- List the types of pressure regulators

- Explain the need for air lubrication

- List the types of air lubricators

Pneumatic actuators use compressed air to create mechanical motion. They perform most of the work in an industrial automated system. There are thousands of configurations of actuators to perform any task you could imagine.

Learning Objectives

- Define a pneumatic actuator

- List the primary types of pneumatic actuators

- Explain how a linear cylinder actuator works

- Explain how a rotary actuator works

- Describe the purpose of an air gripper

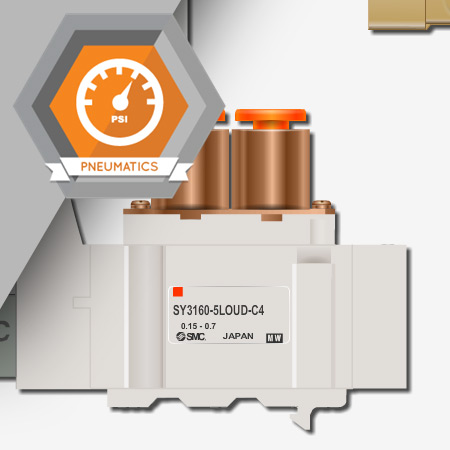

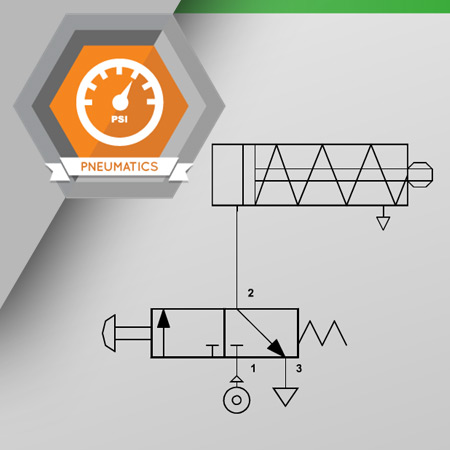

Directional control valves are used to manage the flow of compressed air to and from the pneumatic devices. The use of directional control valves simplifies the job of controlling air flow to multiple pneumatic devices.

Learning Objectives

- Explain the purpose of a directional control valve

- Demonstrate how a directional control valve works

- Understand the types of directional control valves

- Be able to classify directional control valves by their function and method of operation

- Be able to classify them by the manner in which they are actuated

- Identify the type of valve from a schematic symbol

- Explain the different types of valve actuation

Vacuum is a technology used in an automated system to lift and move products and materials. Like pneumatics, vacuum technology is based upon some of the basic laws of science and physics, but with some differences.

Learning Objectives

- Understand the physical laws that are used in vacuum technology

- Explain the importance of pressure when creating a vacuum

- Explain how a vacuum is generated

- List the types of vacuum

- Define the components that are used in a vacuum system

- Identify the symbols that are used for vacuum components

The behavior of a pneumatic system is controlled by the pneumatic variables of pressure and flow. Proper measurement and monitoring of these variables is critical to the performance of the pneumatic system.

Learning Objectives

- Understand pressure

- Understand flow

- Define the instruments that are used to measure pressure and flow

- Explain how these instruments function

- Identify the units of measure for pressure and flow

- Explain the function of pressure and flow switches

There are countless applications of pneumatic technology in the world. Many of the applications share the same components and circuitry logic. In this course, you will learn how to build and operate several pneumatic and electro-pneumatic systems.

Learning Objectives

- Draw basic electro-pneumatic circuits

- Assemble electro-pneumatic circuits

- Use pneumatic symbols to represent electro-pneumatic circuits

- Understand the basic logic of the electro-pneumatic circuits