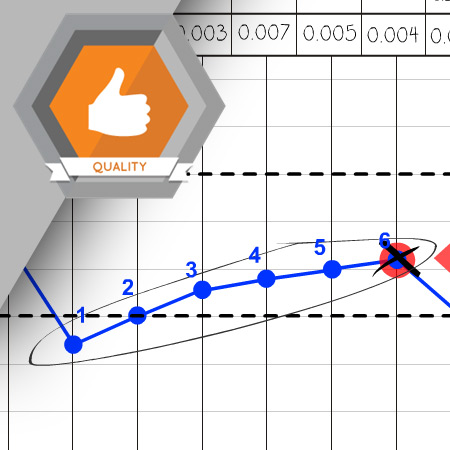

Analyzing the data on your control chart will help you keep your processes in a state of statistical control. This course provides a few rules and guidelines that will help you identify potential problems before the process creates defective products.

Learning Objectives

- Prepare a control chart for analysis

- Explain the eight basic control chart tests

- Analyze the averages chart

- Analyze the range chart

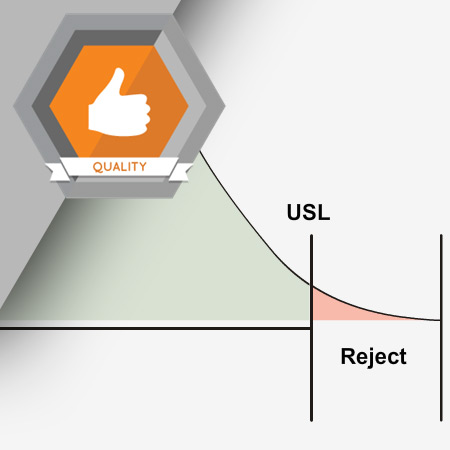

Process capability is a measure of the ability of a process to produce products that meet or exceed the engineering requirements. It is the standard for evaluating the statistical capability of a manufacturing process.

Learning Objectives

- Define process capability

- Define specification limits

- Calculate process capability

- Calculate the process capability index

- Explain how the location of the process mean impacts process capability

Problem solving tools are used to identify the root causes of problems in a process. They are designed to create a methodical path towards problem resolution.

Learning Objectives

- List the seven quality control tools

- Define and explain the seven basic quality tools

- Create a cause-and-effect diagram

- Create a check sheet

- Create a histogram

- Create a pareto chart

- Create basic graphs

Problem solving is one of the most difficult things you will ever do. It requires a strong mind, willpower, and knowledge of problem solving processes to get to the root cause of difficult problems.

Learning Objectives

- Explain the Plan, Do, Check, Act cycle

- Define the required tasks for each step of the Plan, Do, Check, Act cycle

- Identify how the seven quality tools are used in the Plan, Do, Check, Act Cycle