Heat treatment involves the controlled heating and cooling of a metal to obtain desirable changes in its mechanical properties. It can be used to increase the machinability and performance of metals.

Learning Objectives

- Define heat treatment of metals

- Define quenching

- Describe and compare annealing, normalizing, and tempering

- Compare different methods of hardening metals

- Identify which heat treatment methods can be used on various steels and steel alloys

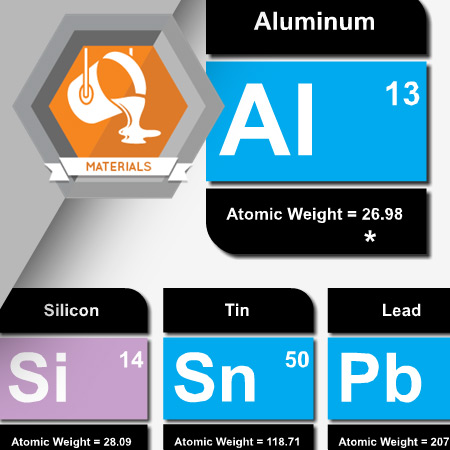

Nonferrous metals include metal elements that are not iron and alloys that do not have iron as their base metal. Some important and widely used nonferrous metal alloys have base elements of aluminum, titanium, copper, magnesium, and nickel.

Learning Objectives

- Define nonferrous metals

- Compare the composition, properties, and uses of aluminum, titanium, copper, magnesium, and nickel alloys

- Identify some of the additional alloying elements used in nonferrous metals and the properties they enhance

- Identify common uses of nonferrous metals

Irons, steels, and their alloys make up the family of ferrous metals. Ferrous metals are the most widely used metals in the world.

Learning Objectives

- Define ferrous metals

- Compare the composition, properties, and uses of cast, wrought, and pig iron

- Compare the composition, properties, and uses of plain carbon, alloy, stainless, and tool steels

- Identify some of the elements used in iron and steel alloys and the properties they enhance

Metal products are used in every industry, including construction, transportation, electronics, manufacturing, medical devices, and consumer products. It is important to understand the properties of metals when designing products and choosing manufacturing processes.

Learning Objectives

- Identify metal products

- Recognize a periodic table and the metals, nonmetals, and metalloids classifications

- Define metals, nonmetals, and metalloids

- Describe and compare the properties of metals, nonmetals, and metalloids

- Explain that metal, nonmetal, and metalloid elements can be combined to form metal alloys

- Explain why machinability is important

- Describe the mechanical properties of metals, including strength, toughness, ductility, malleability, brittleness, and hardness

- Identify and compare methods of testing hardness

- Describe and compare how metal parts are formed and how mechanical properties affect metal forming