Visual testing is the most common method of nondestructive testing. In fact, most nondestructive applications rely on a visual assessment of parts or components prior to applying their specific test inspection method. Without visual testing, discontinuities, such as cracks in aircraft parts, may be missed, potentially leading to life-ending tragedies.

Learning Objectives

- Define nondestructive visual testing

- Understand the history of visual testing

- List applications of visual testing

- Define common terms associated with visual testing

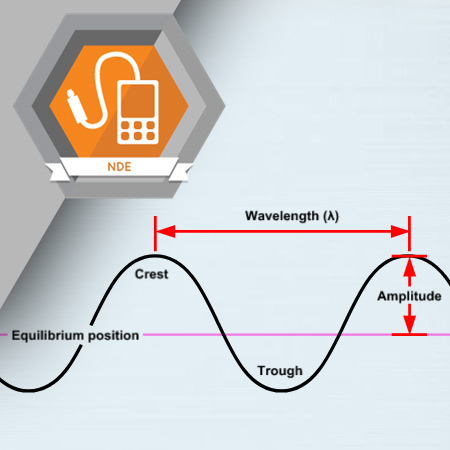

Light and vision are key factors in the success of visual testing. Detecting discontinuities depends on how well a technician can see them, which is influenced by the quantity and direction of light.

Learning Objectives

- Describe the physics of light

- Understand the difference between artificial and natural light sources

- Recognize the effect of different amounts of light and light direction on visual testing

- Define key terms related to light and vision

- Know how to measure illumination

- Understand reflected and refracted light

- Learn about different types of lenses

- Describe how the human eye processes light

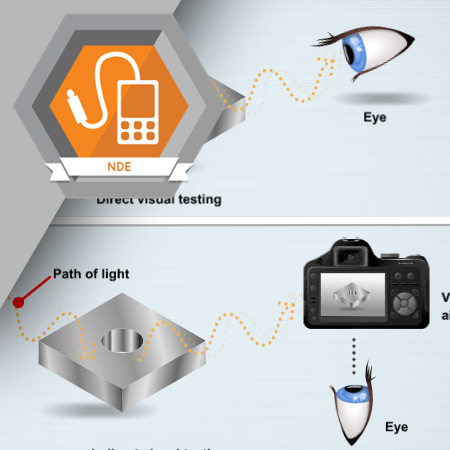

An NDE technician may conduct visual testing directly or indirectly. While direct visual testing gives the technician an uninterrupted line of sight to the test object, indirect visual testing requires the use of visual aids to achieve a line of sight to the test object.

Learning Objectives

- List the basic techniques used in visual testing

- Understand the differences between direct and indirect visual testing

- Understand the difference between local direct visual testing and general visual testing

An NDE technician may use several different types of equipment and optical aids to perform visual testing. In this course, you will discover how a borescope, fiberscope, and videoscope work. You will also learn the roles cameras and resolution charts play in visual testing.

Learning Objectives

- Identify the parts of a borescope

- Understand the differences between a borescope, fiberscope, and videoscope

- Understand the role a camera plays in indirect visual testing

- Identify the parts of an indirect visual test system

In this course, you will find out about the hierarchy of standards, which dictates the general requirements a test product must meet. You will also learn about other standards that may be required and what to do when the standards conflict.

Learning Objectives

- Understand the hierarchy of standards

- List the requirements of the design standard

- Know what to do in case of a conflict between standards

- List what procedure documents need to include

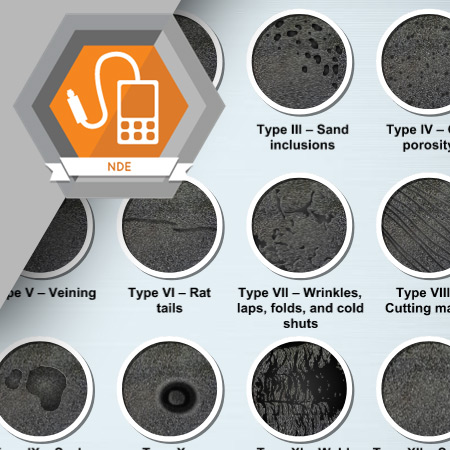

Standards play an important role in visual testing. Depending on the standard required, the NDE technician can compare the test object to photographs, actual replicas of surface irregularities, and written criteria.

Learning Objectives

- Understand how photographs and replicas of surface irregularities are used in visual testing

- Know the differences between comparators for the same type of surface irregularity

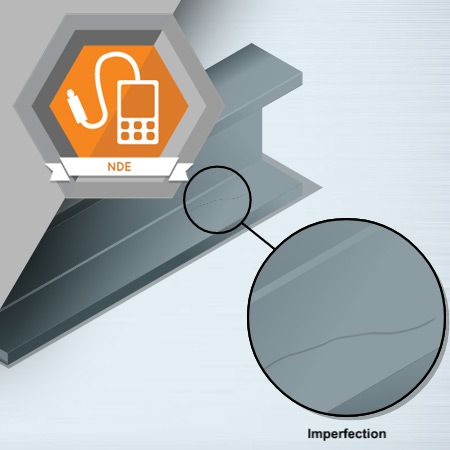

In this course, you will learn the difference between an imperfection and a defect. You will also discover discontinuities common in rolling and drawing.

Learning Objectives

- Understand the difference between an imperfection and a defect

- Recognize typical discontinuities of rolled products

- Know how to measure a discontinuity’s depth

- Identify common discontinuity arrangements

- Understand the process for repairing affected areas

In this course, you will find out about the process of visually testing welds. You will also discover the importance of meeting acceptance standards, as well as the information required on a typical visual test report.

Learning Objectives

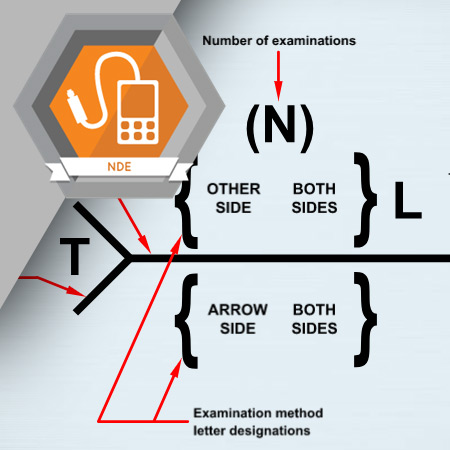

- Understand NDE examination symbols used on engineering drawings or instructions

- Describe the process of visually testing a weld

- Understand when visual testing of a weld may occur

- Understand what to look for during each stage of the welding process

- Know what basic information is needed for a visual test report

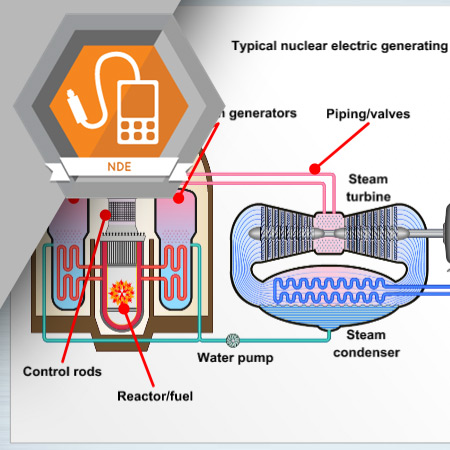

In this course, you will become acquainted with common industrial components, such as storage tanks, pressure vessels, piping, valves, pumps, hangers, and supports.

Learning Objectives

- Understand the working principles of common industrial components

- Describe different types of valves

- Describe three different functions of valves

- Describe different types of pumps

- Describe different types of hangers and supports

- Describe the operation of common industrial components

- Identify discontinuities common in industrial components