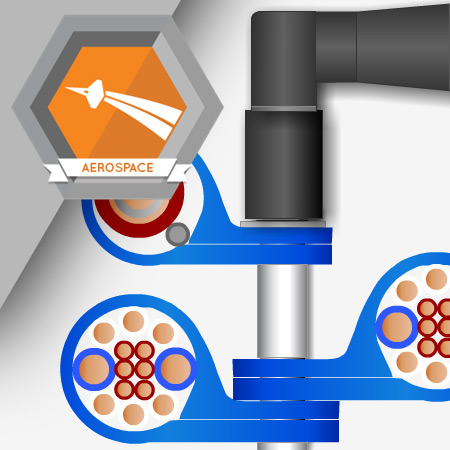

Installing wire bundles correctly in an airplane requires following specific paths and also providing adequate distance between a wire bundle and other bundles or other components.

Learning Objectives

- Understand wire bundle clearance

- Understand wire bundle separation

- List methods to provide separation

- List the problems caused by improper separation

- List the problems caused by improper clearance

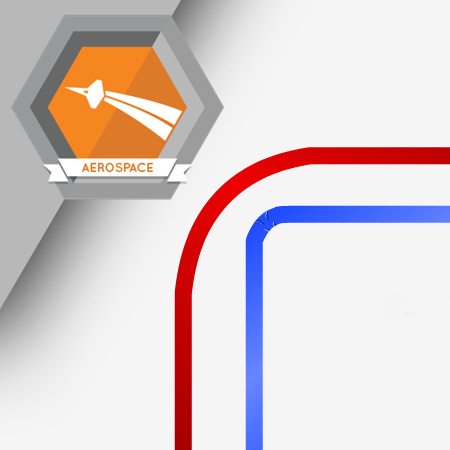

Wire, cable, and wire bundles are flexible, but there are limits to how tightly they can be bent. Understanding these limits is very important to installing wire bundles correctly.

Learning Objectives

- Understand minimum bend radius

- Calculate the minimum bend radius of a wire, cable, and wire bundle

- Define radius and diameter

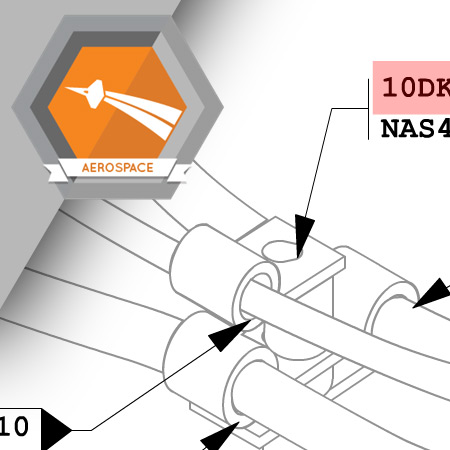

Wire bundles must be clamped to secure them to the structure or equipment of an airplane. Understanding how to clamp a wire bundle is very important to installing wire bundles correctly.

Learning Objectives

- Understand the proper alignment of a clamp to a wire bundle

- List the different types of filler

- List how a properly clamped wire bundle is allowed to move

- List the properties of a properly clamped wire bundle that contains coax cables

- Understand how to distribute slack in a wire bundle

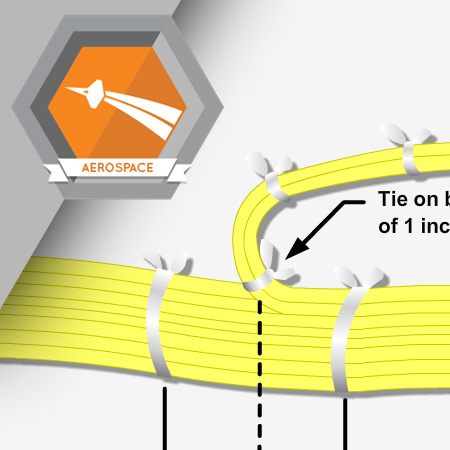

Wire bundles must be tied to prevent vibration of the wires and expansion of the bundle between clamping points. Understanding how and where to tie a wire bundle is very important to installing wire bundles correctly.

Learning Objectives

- List the general tying requirements in different areas of an airplane

- List the parts of a cable tie gun

- Understand the special requirements of tying wire bundles containing fiber optic cables

- Understand how to tie wire bundles where wires exit the bundle

- Tie four different knots with lacing tape

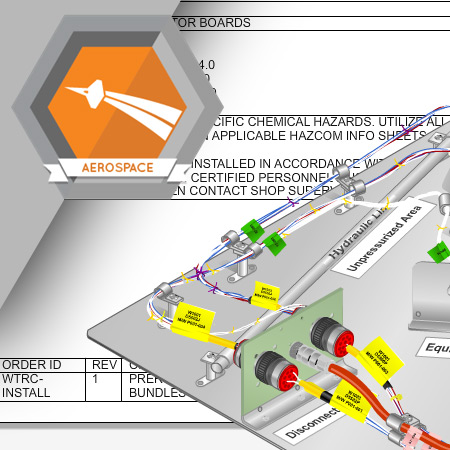

Learning Objectives

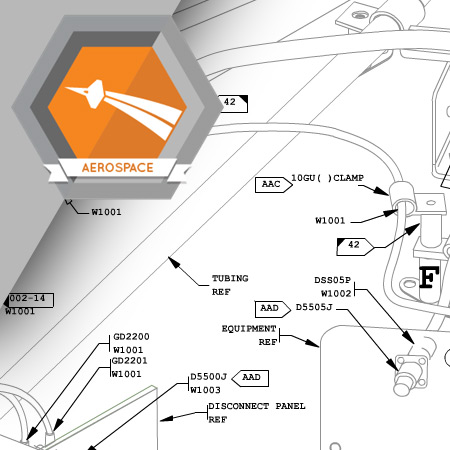

- Understand the sections of an installation plan

- Determine from the installation plan which materials are needed for the project

- Understand specific requirements of the installation plan

- List other installation plans that are associated with this project

Properly installing wire bundles in an airplane requires careful planning. Comparing the area of the installation to the production illustration is an important step in the planning process.

Learning Objectives

- Understand the use of a stand-off

- Identify an attach point bubble on the production illustration

- Use the attach point reference table to identify drawings associated with attach points

- Recognize that a production illustration may represent the completion of several installation plans

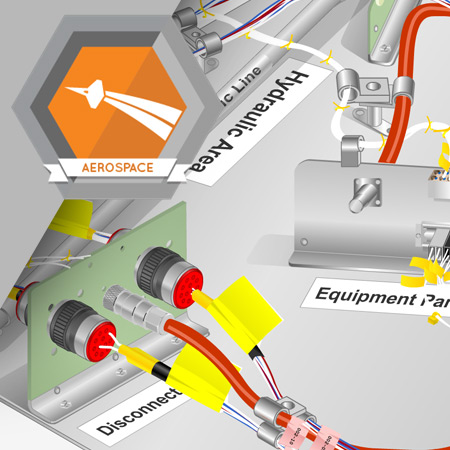

Properly installing wire bundles in an airplane requires carefully laying out the wire bundles along their required paths before clamping them in position. This process is called pre-routing.

Learning Objectives

- Determine the starting point of a wire bundle installation

- Pre-route wire bundles per the production illustration

- Identify and pre-route breakouts

- Identify the proper locations of flag markers

Properly clamping wire bundles in an airplane requires a thorough understanding of the requirements on a production illustration and installation plan.

Learning Objectives

- Identify hardware requirements on a production illustration

- Identify types of clamps required on a production illustration

- Position clamps properly at attach points on a project

- Understand the allowable distance between ties in areas of the airplane

The bolts that hold the wire bundle clamps must be tightened to a specific torque to prevent loosening of the bolt or damage to the components.

Learning Objectives

- Identify the proper torque for a bolt from the information in the installation plan

- List items to inspect upon completion of a wire bundle installation