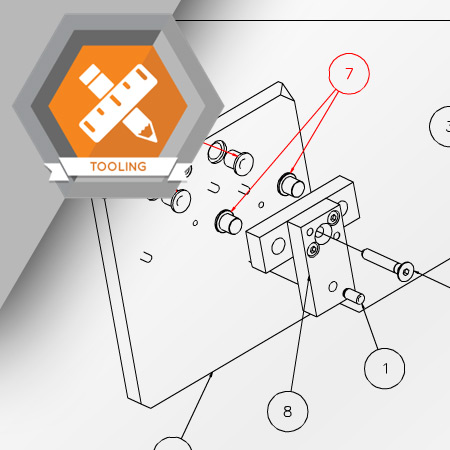

Satisfying critical features and requirements of a tool often determines if a tool is functional. However, it is usually the small details of a tool that determine if the tool is user-friendly. Understanding how to make tools user-friendly is important for anyone wanting to become a toolmaker.

Learning Objectives

- Understand how to layout a clamp for installation

- Understand the importance of deburring

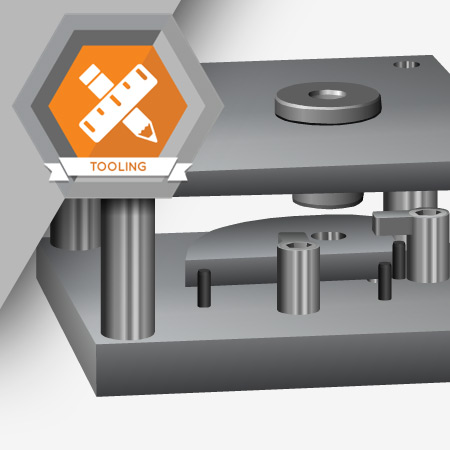

Creating critical features or satisfying critical requirements of a tool is usually the most difficult step in the tool making process. Understanding how this is accomplished is important for any toolmaker.

Learning Objectives

- Understand the purpose of precision locators

- Understand how removability is attained in building a drill jig

Permanent assemblies are often used as components in tools. Understanding how to produce permanent assemblies is an important skill a toolmaker will acquire.

Learning Objectives

- Define a permanent assembly

- Understand the process of making a permanent assembly with screws and dowel pins

- Understand the function of screws and dowel pins in a permanent assembly

A toolmaker must decide on a series of steps, or process, to make a tool. Understanding the reasons behind a process is important information for anyone wanting to be a toolmaker.

Learning Objectives

- Identify critical features of a tool

- Define removability

- Identify critical features or requirements on an engineering drawing

There are many circumstances that create the need for a new tool or modifying an old tool. Understanding the process of defining the need for a tool and the tool design process is important information for a toolmaker.

Learning Objectives

- Understand the need for a new tool

- List some common sources of information for a toolmaker

- Understand the role of the tooling engineer in the making of a tool

- Understand the role of the toolmaker