The efficient manufacturing of any product is highly dependent on the arrangement of the departments, equipment, and personnel within a building. This arrangement is referred to as the facility layout.

Learning Objectives

- Define facility layout

- Identify different classifications of manufacturing facility layouts

- List the advantages of each facility layout

- Recognize the factors that determine which facility layout is chosen

Language: English

Estimated Time (Hrs.): 1.1

Micro-module: No

Micro-module Series: No

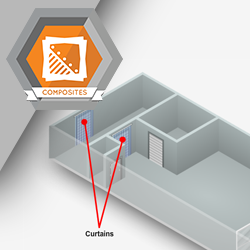

In a composite manufacturing facility, controlled contamination areas are separated from areas that produce contamination or are exposed to contamination.

Learning Objectives

- List areas separated from controlled contamination areas

-

List methods of separating controlled contamination areas from non-controlled areas

Language: English

Estimated Time (Hrs.): 0.7

Micro-module: No

Micro-module Series: No

The layup area is a critical section of a composite manufacturing facility. Proper layout and organization of the layup area is critical to efficiently producing quality composite parts.

Learning Objectives

- List items typically found in the layup area

- List different workstation configurations used in the layup area

Language: English

Estimated Time (Hrs.): 0.8

Micro-module: No

Micro-module Series: No

The curing area is a section of a composite manufacturing facility where materials become true composite parts. Proper layout and organization of the curing area is critical to efficiently producing cured composite parts.

Learning Objectives

- List items typically found in the curing area

-

List common activities of technicians in the curing area

Language: English

Estimated Time (Hrs.): 0.7

Micro-module: No

Micro-module Series: No