In this course, you will learn about the power-off process. The power-off process prepares the CNC machining center to be shut down and then turns the power off.

A CNC machining center requires a program to maximize the machine’s capabilities. Creating a CNC program is only performed after a careful planning stage to determine exactly what machining operations and which part dimensions the CNC machining center will need to machine.

Learning Objectives

- Define a CNC program

- Define the steps in CNC programming

- Understand the importance of thoroughly planning the creation of a CNC program

- Define program zero

- Distinguish between machine zero and program zero

- Explain the relationship between work offsets, machine zero, and program zero

- List methods of creating a CNC program

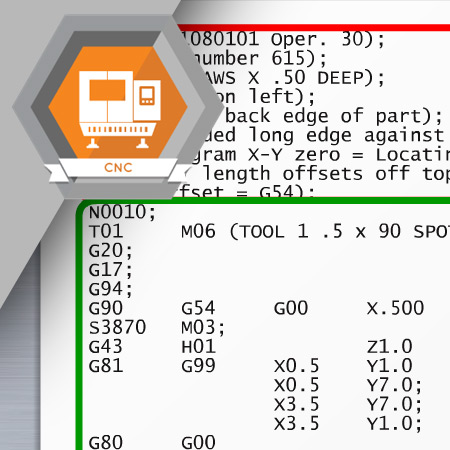

A CNC machining center program is required to be organized in a specific manner for the controller to understand the instructions within the program. Each instruction must also be organized.

Learning Objectives

- Define a stop code

- Define an end of block symbol

- Understand the use of parentheses in a CNC program

- List the two sections of a CNC machining center program

- Distinguish between a block and a word

- Understand the purpose of the program end function

The address of a word in a CNC machining center program defines the meaning of the word. Understanding the meaning of common words in a CNC program is important to recognize what actions the CNC machine tool will perform.

Learning Objectives

- Define the purpose of G codes

- Define the purpose of S, T, and M words

- Understand the importance of G code groups

- Define the meaning of common G codes

- Define the meaning of common M words

- Understand the numeric value of a T word

-

Understand the importance of the format of the numeric data in a word

The instructions written in G code programming that produce an action by a vertical CNC machining center are called commands. A command may require a single word, a block, or multiple blocks.

Learning Objectives

- Understand the requirements to command a tool change function

- Understand the requirements to command a spindle function

- Understand the requirements to command a linear movement

- Understand the requirements to command a circular movement

- Understand the requirements for canned cycle commands

Building a CNC machining center program that is versatile requires organizing sections into an order that will safely produce a part that meets all of the part’s requirements.

Learning Objectives

- List common commands used in each section of the body of a CNC program

-

Define a safe start block